Products

ASRS-Automated Storage and Retrieval Systems

Warehouse Control System - WCSWarehouse Control System ---- WCS

Kingmore Smart focuses on the development of WCS (warehouse control system) and WMS (warehouse management system). We do customize the exclusive software system for each different customers, and connect with other software systems such as ERP and MES.

WCS (warehouse control system)

WCS is a warehouse control systems, and WCS is a management control system between the WMS system and the PLC system. On the one hand, the WCS system interacts with the WMS system, accepts WMS system instructions, and sends them to the PLC system, thereby driving the production line to produce corresponding operations. On the other hand, it reflects the status and data of the PLC system in real time and provides interface debugging for the PLC system and production line. Generally, WCS systems has functions such as automatic access, sorting, and packaging; automatic control and management of production lines; implementation and monitoring of production line dynamics; automatic allocation and execution of production tasks of WMS warehouse management software. In other words, WCS solutions is a system with upstream and downstream operations. Of course, in some applications with fewer devices and single scenarios, such as Mini-Load AS/RS, small devices can also be directly controlled and managed by WCS.

Characteristics

a. Automatic management production line

b. Real time monitoring of production line dynamics

c. Automatically assign production tasks of WMS software

d. Multithreading for efficient operation.

Function

a. Real-time monitoring;

b. Support local amplification and dynamic implementation;

c. Stop, run, fault, disabled status, etc. are displayed in different colors or animations;

d. Provide a parameter setting interface to read the current parameters of the equipment from the PLC;

e. Support parameter initialization and write modified device parameters to PLC;

f. Provide functions such as start, stop, seal, reset, clear, and initialization of conveyor line equipment;

g. Read the barcode information from the PLC, send the barcode information and number to the WMS, and receive the information returned by the WMS;

h. Send task instructions to the PLC, read the PLC task return value, and determine whether it is completed;

i. System, tasks, system failures, and operation logs are retained for customer inquiry.

The difference between WMS and WCS

a. WMS mainly serves business management and report data presentation. Through certain data algorithms, various types of data are calculated and various outputs are obtained.

b. WCS is more related to on-site equipment and materials, and has little intersection with the business level.

c. WMS is mainly responsible for displaying and calculating results, and WCS is mainly responsible for distributing results and uploading data.

d. WMS is the upper-layer system of WCS, as shown in the following diagram:

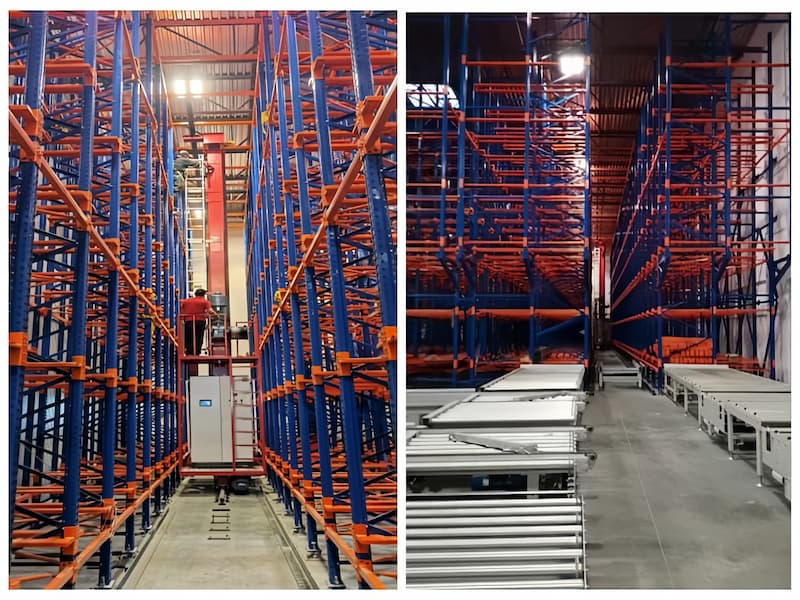

Project pictures

Food industry case : Taian Mengniu dairy automatic three-dimensional warehouse project

Equipment scale: total shelf height of 21 meters, 18,200 cargo spaces; 8 sets of stackers; one conveyor line system, 1 WMS system, and 1 WCS system.

Cold storage food industry case: Canadian Watson food

Equipment scale: total shelf height 11 meters, 21,000 cargo spaces; 4 sets of normal temperature stackers, 2 sets of refrigerated stackers, 2 sets of refrigerated stackers; 3 sets of conveyor line systems, 1 set of WMS system, 1 set of WCS system.

Electrical industry case : Shandong Taikai parts warehouse project

The total height of the shelf is 8 meters, 1,000 cargo spaces, 1 set of stacker, 1 set of conveyor system, 1 set of WMS system, and 1 set of WCS system;

Machinery manufacturing industry case : Jiangsu Tailong reducer stereoscopic warehouse phase II

Equipment scale: The total shelf height is 22 meters, 27,000 cargo spaces, 8 sets of stackers, 1 set of conveyor system, 1 set of WMS system, and 1 set of WCS system;

Machinery manufacturing industry case : Jiangsu Huayan ship parts warehouse

Equipment scale: total shelf height 13 meters, 5600 cargo spaces, 2 sets of stackers, 1 set of conveyor system, 1 set of WMS system, 1 set of WCS system

Tire Industry Case : Kumho Tire Co., Ltd., Vietnam

Equipment scale: The total shelf height is 28 meters, with 53,600 tire positions; 10 sets of stackers; 1 set of conveyor line system, 1 set of WMS system, and 1 set of WCS system.

Add: RM. 1204, BLDG.-2, NEW SPACE DEVELOPMENT CENTER, NO.126 TIANYUAN RD., JIANGNING, NANJING, CHINA.

Copyright 2025@ Jiangsu Kingmore Storage Equipment Manufacturing Co., Ltd All Rights Reserved.

Sitemap

| Blog

| Xml

| Privacy Policy

Network Supported

Network Supported