Products

Storage Racks

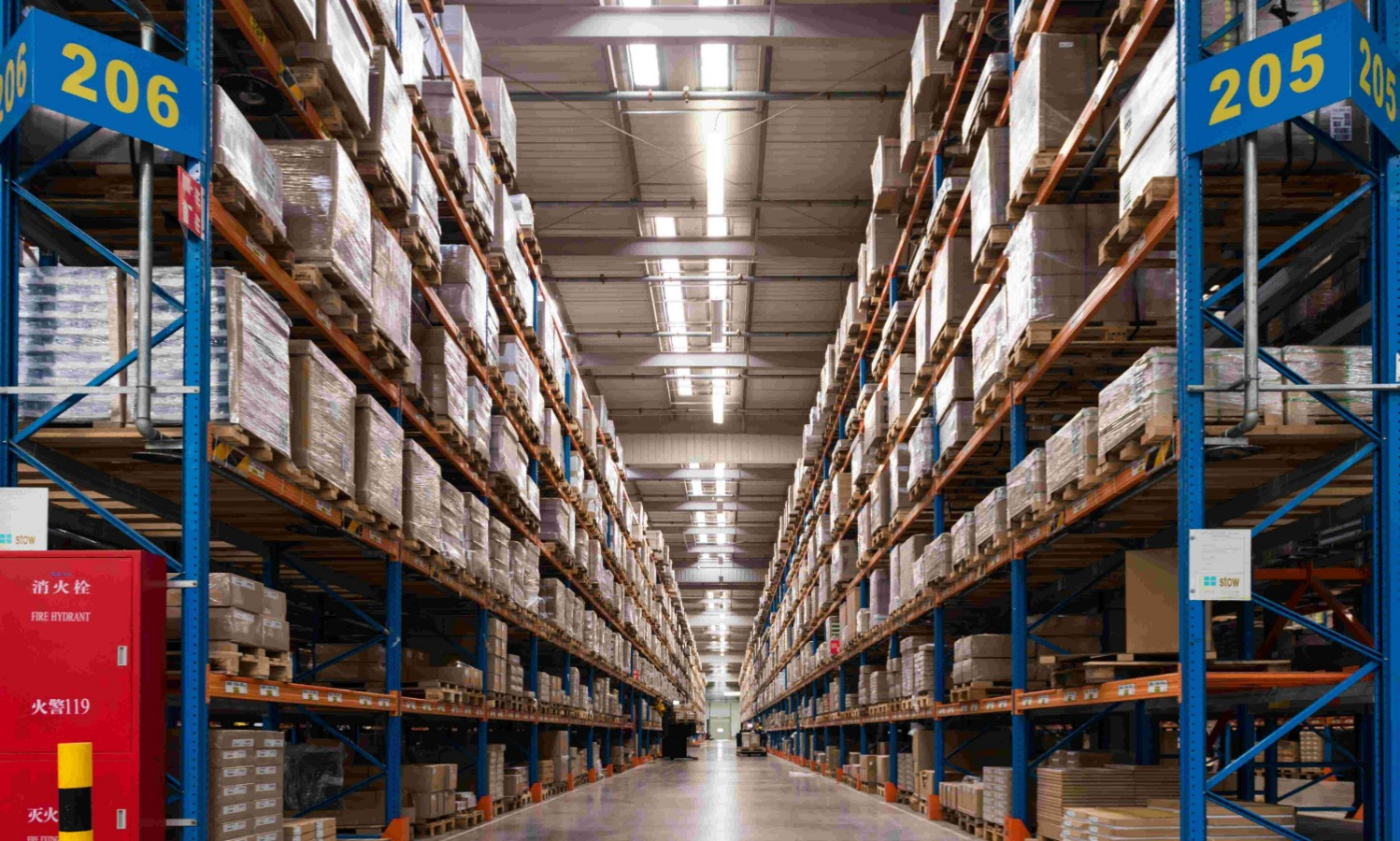

Selective Rack / Pallet Rack / Heavy Duty RackOne of the most common features of any warehouse is the use of industrial pallet racking. These are our most heavy-duty storage racks. Metal pallet racks are designed to have pallets loaded and unloaded using forklifts. They are efficient because you don’t have to manually do any of the heavy lifting. Pick a pallet up off a truck and immediately place it where it belongs on a rack. These industrial pallet racks are versatile. Store other bulky items such as furniture or lots of lighter items.

We provide in-house testing facility to ensure the proper system design to fit your pallet, product, and workflow. Rail types, rail pitch, roller quantity and brake roller spacing are customized, then go through very thorough and system testing to ensure the positive rates of flow for the long haul.

Selective rack, also known as selective pallet rack, is a common type of racking system used in warehouses and distribution centers for organized and accessible storage of palletized goods. It is designed to allow easy access to individual pallets stored at various levels within the rack. Here is a detailed description of selective rack:

Structure and Components:

Selective rack typically consists of the following components:

Uprights: Uprights are vertical columns that form the frame of the rack system. They are spaced apart and connected by horizontal and diagonal braces to provide stability and support to the structure. Uprights have regularly spaced holes or slots along their height to accommodate beams.

Beams: Beams are horizontal load-bearing elements that connect the uprights. They rest on the holes or slots in the uprights and provide the surface on which pallets are placed. The beams are adjustable and can be positioned at different heights to accommodate pallets of varying sizes.

Wire Decking or Pallet Supports: Optional wire mesh decking or pallet supports can be added to the beams to provide additional support for pallets and improve safety by preventing small items from falling through the racks.

How It Works:

Selective rack operates in the following manner:

Rack Installation: Uprights are anchored to the floor, and beams are inserted into the uprights at the desired levels to create shelving tiers. The spacing between the beams can be adjusted to accommodate different pallet heights.

Pallet Placement: Pallets are loaded onto the beams from the aisle using forklifts or other material handling equipment. Each pallet is placed directly on the beams, allowing easy access to individual pallets without the need to move other pallets.

Accessibility: Selective rack offers good accessibility, as each pallet can be reached directly from the aisle. This makes it suitable for high turnover or frequently accessed products.

Load Capacity: The load capacity of selective rack depends on factors such as the size and gauge of the uprights and beams, the distance between the beams, and the weight distribution of the stored goods. The rack system should be designed and engineered to support the intended load requirements.

Advantages:

Selective rack offers several advantages:

Accessibility: Each pallet can be accessed directly from the aisle, ensuring easy placement and retrieval of goods. This enables selective picking and rapid order fulfillment.

Flexibility: Selective rack can accommodate pallets of various sizes and weights. The adjustability of the beams allows for customizable storage configurations to meet changing needs.

Space Utilization: The design of selective rack optimizes vertical storage space, making it suitable for warehouses with high ceilings. It maximizes storage density by utilizing the available height.

Cost-Effective: Selective rack is considered a cost-effective storage solution, as it does not require specialized equipment or complex systems. It is relatively easy to install, maintain, and reconfigure when necessary.

Compatibility: Selective rack is compatible with various material handling equipment, including forklifts, pallet jacks, and order pickers. This allows for efficient and safe movement of goods within the warehouse.

In summary, selective rack is a widely used racking system that provides accessible and versatile storage for palletized goods. With its individual pallet access, adjustability, and compatibility with various equipment, it offers flexibility, efficiency, and optimal space utilization in warehouse operations

Add: RM. 1204, BLDG.-2, NEW SPACE DEVELOPMENT CENTER, NO.126 TIANYUAN RD., JIANGNING, NANJING, CHINA.

Copyright 2025@ Jiangsu Kingmore Storage Equipment Manufacturing Co., Ltd All Rights Reserved.

Sitemap

| Blog

| Xml

| Privacy Policy

Network Supported

Network Supported