Products

Storage Racks

Live Pallet Racking Systems - Pallet Flow RackThe Live Storage Pallet Racking compact structure uses slightly inclined roller beds on each level to allow unit loads to be moved more easily.

Our live pallet racking systems are perfect for businesses that need to rotate stock, particularly where products have a best before date or short shelf life. Offering high-density storage, live pallet racking is designed to support a first-in, first-out (FIFO) system, without the need for special handling equipment.

We provide in-house testing facility to ensure the proper system design to fit your pallet, product, and workflow. Rail types, rail pitch, roller quantity and brake roller spacing are customized, then go through very thorough and system testing to ensure the positive rates of flow for the long haul.

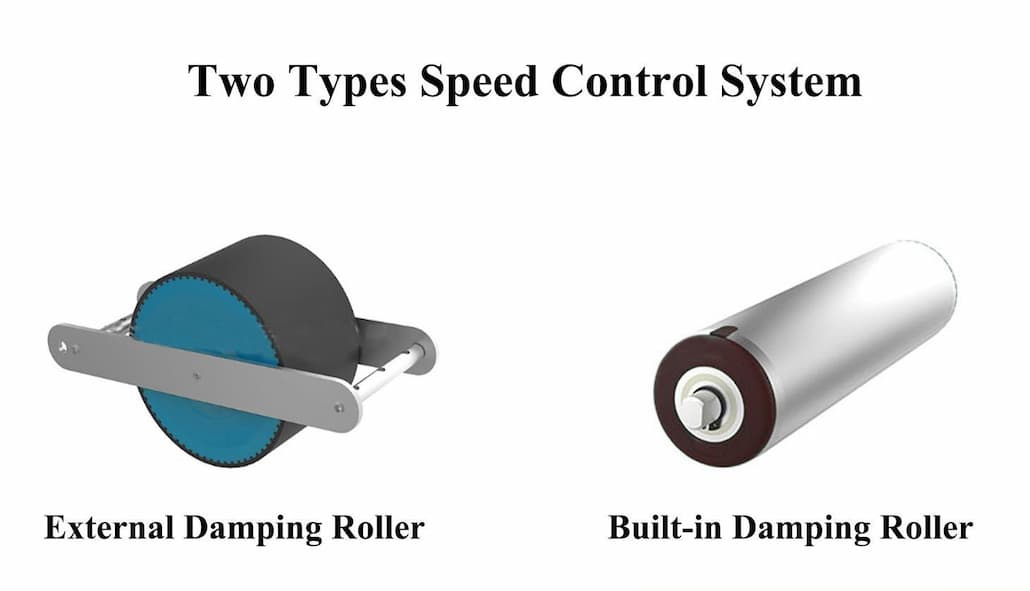

Live racking is a high density and low energy consumption storage system. It is also called gravity racking and pallet follow racking. The pallet is supported by steel rollers and slide down from entrance side to exit side along the sloping roller conveyor. The brake installed in the roller system can control the sliding speed of pallet. The safety separator can separate the first pallet from the following one at the exit side so that forklift can easily take away the pallets. By this way, first-in-first-out working mode can be realized. Live racking is first in first out storage system. Due to this working mode, live racking is widely used in many industries which have requirement on guarantee period, such as food, pharmacy, beverage, chemistry and so on.

FEATURES OF KINGMORE LIVE RACK

APPLICATIONS

DETAILS OF KINGMORE LIVE RACK

Add: RM. 1204, BLDG.-2, NEW SPACE DEVELOPMENT CENTER, NO.126 TIANYUAN RD., JIANGNING, NANJING, CHINA.

Copyright 2025@ Jiangsu Kingmore Storage Equipment Manufacturing Co., Ltd All Rights Reserved.

Sitemap

| Blog

| Xml

| Privacy Policy

Network Supported

Network Supported