Automated Storage and Retrieval Systems (ASRS) can vary in cost depending on various factors such as the size of the system, complexity, customization, and additional features. ASRS systems are generally considered a significant investment due to their advanced technology and ability to streamline warehouse operations. However, it's important to note that the specific cost of an ASRS system will depend on the specific requirements of the warehouse and the chosen system provider.

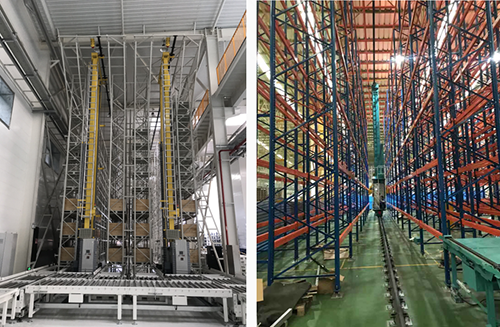

ASRS systems typically include infrastructure components such as racks, stacker cranes, conveyors, and control software. They automate the process of storing and retrieving goods in a warehouse or distribution center, reducing the need for manual labor and improving efficiency. By utilizing advanced robotics, sensors, and software control systems, ASRS systems can perform tasks such as automatically locating and retrieving items from designated storage locations, optimizing space utilization, and providing real-time inventory management.

The cost of implementing an ASRS system involves several elements, including the initial capital investment for equipment, installation costs, integration with existing warehouse systems, maintenance and support expenses, and training for personnel. Additionally, ongoing operational costs such as energy consumption, equipment servicing, and software updates should be considered.

The ASRS system can contribute to streamlined operations, better inventory management, faster order fulfillment, and ultimately, improved customer satisfaction. It's definitely cost-effective to build the system and please contact Kingmore a professional manufacturer to learn more if you are interested in it.

By Amy

Add: RM. 1204, BLDG.-2, NEW SPACE DEVELOPMENT CENTER, NO.126 TIANYUAN RD., JIANGNING, NANJING, CHINA.

Copyright 2025@ Jiangsu Kingmore Storage Equipment Manufacturing Co., Ltd All Rights Reserved.

Sitemap

| Blog

| Xml

| Privacy Policy

Network Supported

Network Supported